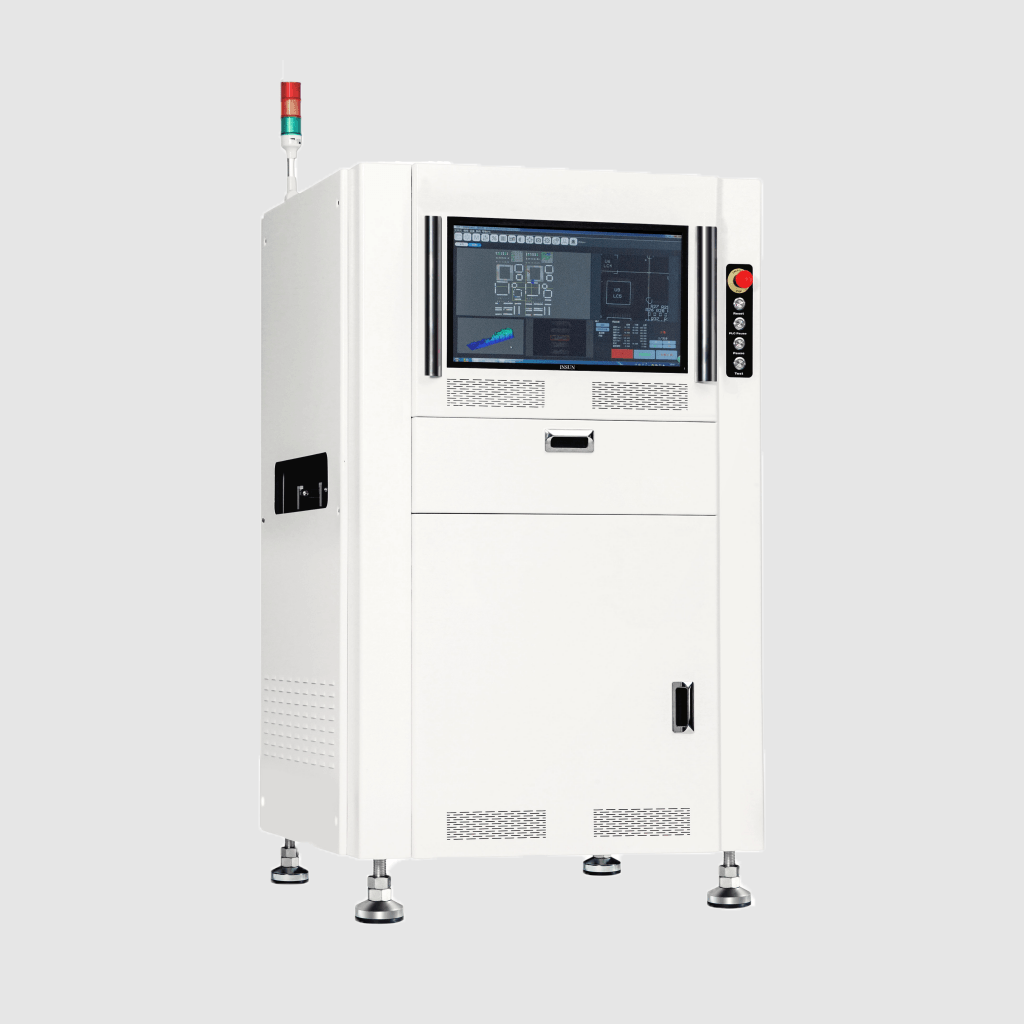

AOI Inspection Machine

Key Features of aoi inspection machine:

- High-Resolution Imaging: Our AOI inspecion Machine employs high-resolution cameras and advanced imaging algorithms to capture detailed images of each PCB. This allows for thorough inspection of the smallest components, solder joints, and traces, ensuring no defect goes unnoticed.

- Defect Detection: With its intelligent defect detection system, our AOI Machine can identify a wide range of defects, including soldering issues, misalignments, missing components, shorts, open circuits, and more. It performs comprehensive inspections, ensuring the highest level of quality and reliability.

- Fast and Efficient: The AOI inspection Machine is designed for speed and efficiency. It can inspect PCBs at a rapid pace, significantly reducing inspection time and increasing productivity. This enables faster turnaround times and streamlined production processes.

- Real-time Feedback: Our machine provides real-time feedback and analysis, allowing operators to quickly identify and address any issues that arise during the inspection process. This immediate feedback loop enables prompt corrective actions, minimizing production delays and optimizing quality control.

- Customizable Inspection Criteria: Tailoring the inspection criteria to your specific requirements is a breeze. It offers flexible customization options, allowing you to define inspection parameters, tolerance levels, and defect classification rules. This ensures that the machine adapts perfectly to your quality standards.

- User-Friendly Interface: The AOI inspection Machine features a user-friendly interface with intuitive controls and a visual display. Operators can easily navigate through inspection results, review images, and generate reports. The interface facilitates smooth operation and simplifies data analysis.

- Data Analysis and Reporting: Our AOI Machine is equipped with powerful data analysis capabilities. It can generate detailed inspection reports, complete with images, statistics, and defect classifications. This data is invaluable for process improvement, quality tracking, and customer documentation.

- Seamless Integration: Our AOI inpection Machine seamlessly integrates with existing production lines, complementing other equipment and processes. It can be connected to upstream and downstream machines, ensuring a smooth flow of PCBs and enabling comprehensive quality control throughout the production cycle.

| CATEGORY | ITEM | SPECIFICATION |

|

Recognition System

|

Inspection | The vector image algorithms include logic operation, distance of luminance boundary, chip tracing, OCR/OCV, luminance/color template matching, color distance, color extraction(RGB & HSV), value-range of luminance, offset of luminance, the minimum variation span of luminance, etc… More than 30 kinds of the most advanced algorithms. |

| Camera | Digital high speed 5M Pixel camera | |

| Resolution | 20um(15um for option) | |

| Lens | High-resolution telecentric Lens | |

| Depth of focus | 5mm (High depth of field lens can be selected for special requirements) | |

| Lighting Source | 4 channel Rings RGBW LED lighting. | |

| FOV | 40×40mm (20um)

Or 30×30mm(15um) |

|

| 0201 Chip | <7.6ms | |

| Per-image Time | 220~450ms | |

| Paste Printing Defects | Missing, overflow, insufficient, pasting open, stain | |

| Component Defects | Missing, shift, skewed, tombstone, billboard, overturned, reversed polarity, wrong, damaged | |

| Solder Defects | Overflow, insufficient, short solder, stain | |

| Wave Soldering Inspect | Overflow, insufficient, short, Excess Solder, solder void | |

| Inspection Items | 0201&0.4mmpitch (20um)

01005& 0.3mm pitch(15um) |

|

|

Mechanical System |

PCB Conveyor |

Left to right(Optional, right to left)

PCB fixing: bottom-up, PCB warp correction. Automatic PCB loading and unloading, Adjustable clearance, Conforming SMEMA standard. Orbit clearance: 900±20mm |

| PCB Size | 50×70mm-400×330mm | |

| PCB Thickness | 0.5mm – 3.0mm | |

| PCB Warp Tolerance | <2mm(Fixture-assisted deformation correction) | |

| Component Clearance | TOP≤30mm, BOT≤30mm(customized for special requirements) | |

| Driver | AC server, camera moves in the directions of X/Y. | |

| Orientation | <10um | |

| Moving Speed | Standard:500mm/s,Max:800mm/s | |

|

Soft System

|

Operation System | Microsoft Windows Win10 X64 |

|

Characteristic |

Basis on Vector analysis algorithm, integrated variety of software algorithms of Color Extraction、 Luminance Extraction 、Color Distance,for SMT components and the position of the solder joints , appearance , accurate positioning and analysis accurately eliminate all kinds of bad points | |

| Operation | Graphic programming, Chinese, English | |

| Programming | CAD、handwork programming, Support offline programming(Optional) | |

|

Computer |

Industrial Computer, Intel four-core I7 CPU, Memory:16G, Hard disk: 2TB | |

| Display | 21 inch TFT | |

|

Network |

Multi machine control | The operator can control multi same machines in the control terminal |

| Network | NG adaptable, check and correct PCBA defects at repair station | |

| Communication port | SMEMA, RS232,RJ45 | |

|

Other

|

Air Supply | 0.5MPA.80cm³/min |

| Machine Dimensions | 100×96×160cm | |

| Weight | ~670kg | |

| Power Supply | AC220V, 10%, single phase 5A 50/60HZ, power consumption 1000W with UPS inside | |

| Working Environment | Temperature10-40℃, humidity 30-80% RH |