Table of Contents

Introduction:

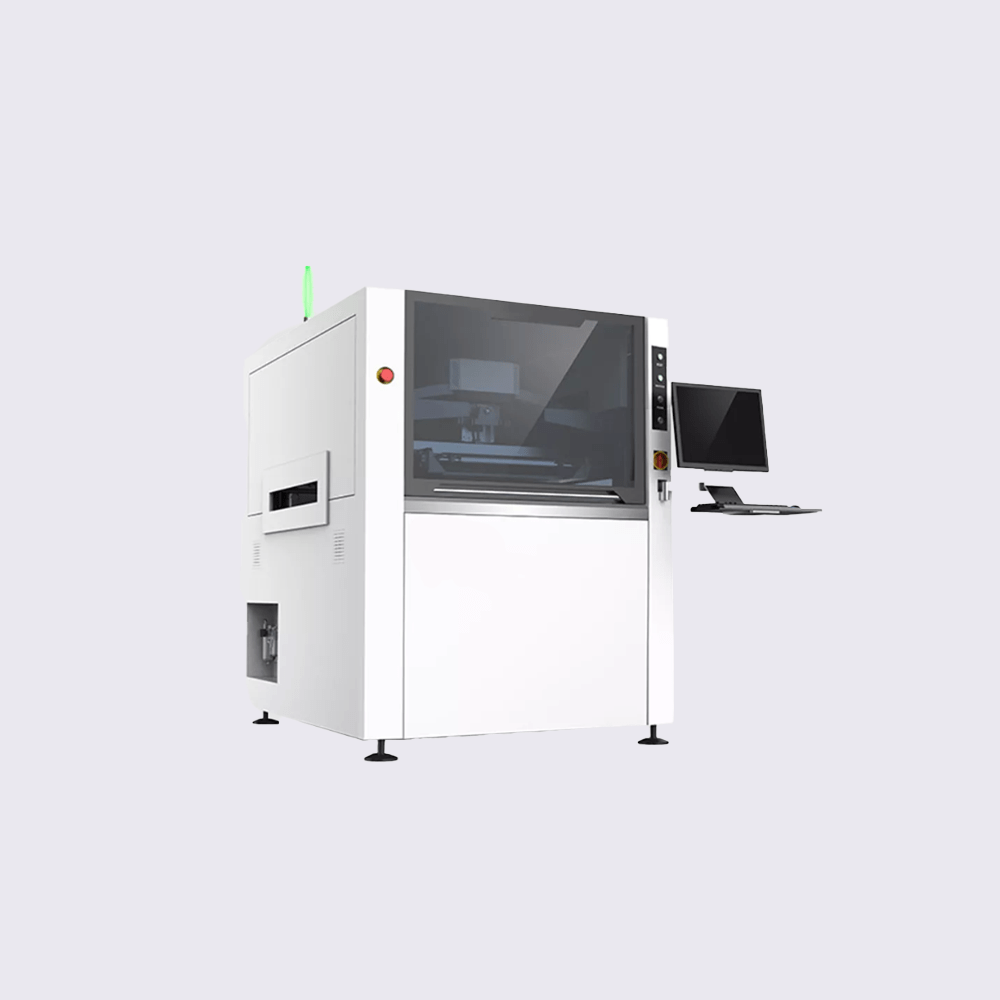

In the world of electronics manufacturing, having a reliable and efficient SMT line is crucial for producing high-quality products. One essential component of the SMT line is the solder paste printer, which plays a vital role in accurately applying solder paste to the PCB. In this guide, we will explore the key factors to consider when purchasing a solder paste printer for your SMT line, ensuring that you make an informed decision. Factors to consider include the type of solder paste the printer uses, the printing speed, and the accuracy of the printing.

Additionally, it is important to consider the features of the printer such as the number of heads, the print head size, and the cost of the machine. Finally, it is important to ensure that the printer is reliable and easy to maintain, as this can be a key factor in determining the overall value of your investment.

Section 1: Understanding the Importance of a Solder Paste Printer

A solder paste printer is responsible for precisely depositing solder paste onto the PCB pads, forming the solder joints that connect the components. This crucial step in the SMT process directly impacts the quality and reliability of the final product. By choosing the right solder paste printer, you can enhance the efficiency, accuracy, and overall performance of your SMT line. Additionally, a well-designed solder paste printer can help to reduce rejects and production downtime. A properly designed solder paste printer is a valuable asset for any SMT line and should be carefully selected and properly maintained.

Section 2: Factors to Consider When Choosing a Solder Paste Printer

2.1 Printing Accuracy and Precision:

Achieving consistent and accurate solder paste deposits is essential for the success of your SMT line. Look for a solder paste printer that offers advanced vision systems, high-resolution cameras, and precise control mechanisms to ensure precise alignment and positioning. It is also important to ensure that the solder paste is accurately dispensed and evenly applied. Check for automated features that can help to reduce manual labor and the potential for human error. Finally, look for a printer that offers reliable service and support.

2.2 Throughput and Speed:

Consider the production volume and demands of your SMT line. A solder paste printer with a high throughput rate and fast printing speed can significantly improve the overall productivity of your manufacturing process. A reliable solder paste printer can also reduce the chance of human error and increase the accuracy of the production. In addition, it can help you save money by eliminating the need for manual printing.

2.3 Versatility and Compatibility:

Evaluate the compatibility of the solder paste printer with various PCB sizes and types. Look for flexibility in terms of stencil sizes, board support systems, and adjustable printing parameters to accommodate different production requirements.

Section 3: Advanced Features and Technology

3.1 Automatic Optical Inspection (AOI):

Some solder paste printers come equipped with integrated AOI systems, which can inspect the printed solder paste for defects or inconsistencies. This feature helps in identifying and rectifying issues early on, saving time and minimizing rework. This helps to ensure that the solder paste is printed accurately and without any defects. Additionally, AOI systems can also help to detect potential solder defects, such as solder bridges or solder balls, which can lead to short circuits or other issues.

3.2 Software Integration and User-Friendly Interface:

Efficient software integration and an intuitive user interface can streamline the operation of the solder paste printer. Look for printers with user-friendly software that allows for easy programming, quick setup, and real-time monitoring of the printing process.

Section 4: Budget Considerations

Investing in a solder paste printer is a significant decision for any electronics manufacturer. It is crucial to determine your budget and explore options that offer the best value for money. Consider factors such as initial cost, maintenance expenses, and potential return on investment when selecting a solder paste printer. Additionally, it is important to consider the printer’s capabilities, features, and compatibility with your existing equipment. Finally, make sure to compare the features and benefits of different models and brands to choose the best one for your application. After you have selected a printer, it is important to get input from experienced users to ensure you have made the best decision. Finally, make sure you receive proper training on its use to maximize your productivity.

Conclusion:

Choosing the best solder paste printer for your SMT line is a critical step in optimizing your electronics manufacturing process. By considering factors such as printing accuracy, throughput, versatility, advanced features, and budget, you can make an informed decision that aligns with your production requirements and goals. Remember, investing in a reliable and efficient solder paste printer will contribute to the overall success and quality of your SMT line.

With the proper selection of a solder paste printer, you can significantly reduce costs and improve yield. It is important to research and compare different options to determine which one best suits your workflow. You can also consult with a knowledgeable sales rep for assistance.