LED LENS SMT LINE

For High End Lighting Industry

Assemby Ability

From Standard Line

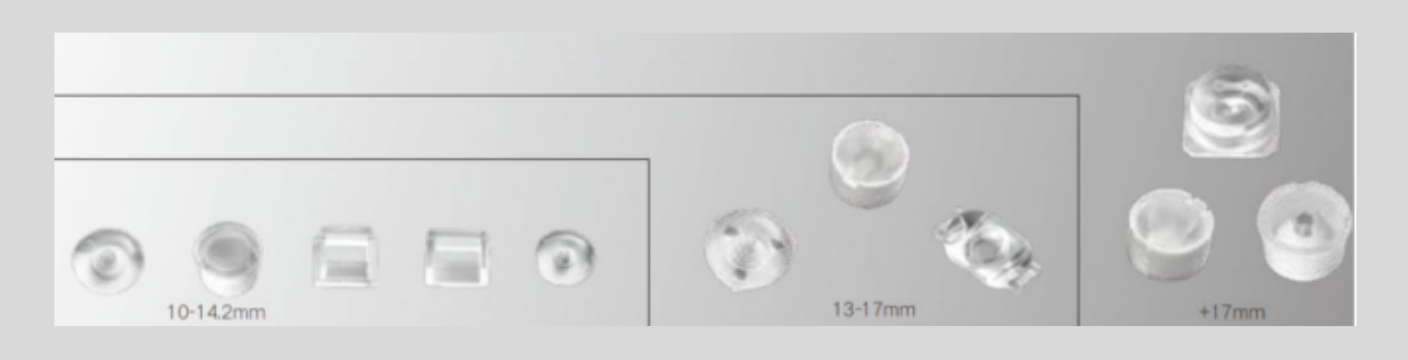

From Lens Line From 10mm to 17mm lens, L8 as the dominant equipment which can handle the different types of lens for your light product

Before

After

What is Led Lens SMT LINE?

An Led Lens SMT LINE is similiar to led smt line. The main purpose is to place the Lens beads on the surface led pcb board with the help of glue dispenser machine and a led lens pick and place machine.

Basic Process

At first the operator loads the led pcb board in the pcb loader machine. The pcb loader starts loading the pcb board to the glue dispenser machine. Glue dispenser machine applies the glue on the pcb board with the help of glue valve . The application speed of glue dispenser is about 18000 dots per hours. The Glue Types used for this application process is Epoxy resin Glue or UV glue from dowsil or kafuter brand.

Placement Process of Lens Beads

Now the PCB board is ready for the placement of lens beads. The led lens pick and place machine start placing the lens beads on the surface of pcb board with its robot like head which consists fo 8 spindles.

The Led Lens beads are loaded in the bowl feeder of the smt mounter the bowl feeder produces powerful vibration to feed the in the feeder line. Automated pick and place machine places the components on the surface of pcb board with the speed of 15000 component per hour (CPH) to 25000 (CPH) please note that the speed of smt machines depends on the component type. In case of Led lens the average speed is 15000 (CPH).

Soldering of PCB board

The PCB board is ready for the soldering process which can be done by reflow oven or UV oven. Hot air lead free reflow oven is required to solder the Epoxy resin glue meanwhile UV reflow oven is required to solder the UV glue.

Strength of Glue

If we compare the strength of glue the expoxy resin glue has more stronger strength compared to UV Glue. But epoxy glue required has low temperature to store at least -20 degree celcius while UV glue can be stored at room temperature.

List of Equipments Required

Where to purchase these Equipments

As purchasing an equipment for production is very important because all the production of a factory is dependent of the equipment. In case of chossin the wrong equipment or manufacturer may lead to loss of huge investment. We suggest you always choose the reliable supplier for your equipment that can provide you the best service to start the production.

As we are the leading supplier of smt line industry specially in led placment process. Faroads provide the equipment with at least 1 year of warranty and onsite after service .

Budget Required

let us calculate the exact budget required to setup the complete led lens pcb board production line.

Equipment cost

- PCB loader cost varies 2500-4000 usd

- Glue dispenser cost caries 15000-25000 usd

- Conveyor cost caries 500-800 usd

- led lens pick and place machine cost varies 30000-50000 usd

- Reflow oven cost varies 10000-25000 usd

Note the upper mentiond cost are the industry cost of equipment for specific quotation click get quote now !

Conclusion

Starting a Led Lens SMT line requires meticulous planning, attention to detail, and a focus on continuous improvement. By considering factors such as equipment and infrastructure, skilled workforce, and material selection, you can lay a strong foundation for a successful SMT line